In robotics, precise navigation and movement are crucial for success. The mecanum drive template odometry vex v5 platform, known for its adaptability and user-friendliness, offers immense opportunities for creating advanced robotics systems. Among the various drive systems available, the Mecanum drive stands out for its versatility and maneuverability. Coupled with odometry, it becomes a powerful tool for accurate positioning and navigation. This article delves into the essentials of the mecanum drive template odometry vex v5, covering everything from its fundamental concepts to practical implementation.

What Is a Mecanum Drive?

A mecanum drive template odometry vex v5 drive uses specially designed wheels that enable a robot to move in any direction without needing to turn. These wheels have rollers mounted at a 45-degree angle, which allows for omnidirectional movement.

Key Features of a Mecanum Drive:

- Omnidirectional Movement: Move forward, backward, sideways, or diagonally with ease.

- Flexibility: Ideal for tight spaces and dynamic tasks.

- Complex Control: Requires precise motor coordination for smooth motion.

Understanding Odometry in Robotics

Odometry is a method of tracking a robot’s position and orientation using data from its sensors. In the context of the mecanum drive template odometry vex v5 system, odometry combines wheel encoder readings with mathematical algorithms to calculate a robot’s movement.

Advantages of Using Odometry:

- Precise Navigation: Essential for autonomous tasks.

- Path Planning: Allows for accurate route adjustments.

- Consistency: Reduces reliance on external markers or GPS.

Combining Mecanum Drive and Odometry

The fusion of Mecanum drive and odometry creates a system capable of exceptional maneuverability and precise navigation. However, achieving this synergy requires careful planning and programming.

Why Combine Them?

- Enhanced Agility: Mecanum wheels enable smooth and dynamic movement.

- Positional Awareness: Odometry ensures accuracy in navigation.

- Autonomous Capabilities: Perfect for tasks like game field navigation or obstacle avoidance.

Getting Started with mecanum drive template odometry vex v5

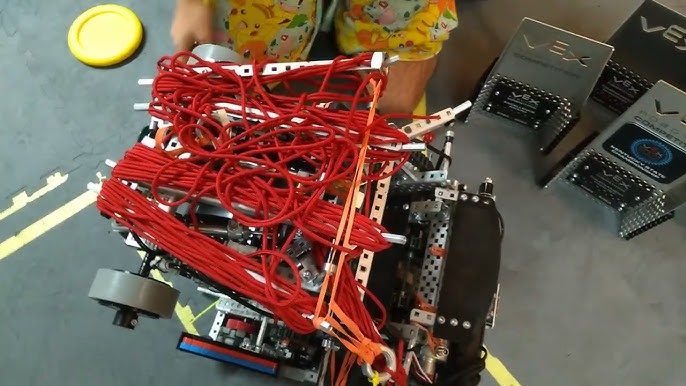

Step 1: Hardware Requirements

To build a mecanum drive template odometry vex v5 drive with odometry, you will need:

- VEX V5 Robot Brain: The central processing unit.

- Mecanum Wheels: Four wheels for omnidirectional movement.

- Motors: High-torque V5 motors for powering the wheels.

- Sensors: Rotary encoders or VEX integrated motor encoders for odometry.

- Chassis: A stable frame to mount the components.

Step 2: Software Setup

VEX V5 robots are programmed using VEXcode Pro V5 or similar platforms. For odometry, you’ll need to implement custom algorithms or use prebuilt templates.

Step 3: Calibration

Calibration is critical for accurate odometry.

- Wheel Measurements: Ensure precise measurements of wheel diameter and spacing.

- Encoder Values: Test and adjust encoder readings for consistency.

Implementing Mecanum Drive Odometry

Programming the Mecanum Drive

The movement of a Mecanum drive requires specific motor power distributions.

Power Distribution:

- Forward/Backward Motion: All wheels rotate in the same direction.

- Lateral Movement (Sideways): Opposing diagonal wheels rotate in opposite directions.

- Diagonal Motion: Combine forward/backward and lateral movements.

- Rotation: All wheels rotate in opposing directions to spin the robot.

Odometry Integration

Core Components:

- Pose Tracking: Determines the robot’s x, y coordinates and heading angle.

- Sensor Data: Reads encoder values to compute distance traveled.

- Mathematical Models: Uses trigonometry to calculate positional changes.

Steps to Implement Odometry:

- Initialize Sensors: Set up encoders to track wheel rotations.

- Calculate Displacements: Convert encoder readings into positional changes.

- Update Position: Continuously update the robot’s pose using integration.

- Feedback Loop: Use odometry data to adjust motor power for precise movement.

Tips for Optimizing Performance

- Ensure Proper Alignment: Misaligned wheels can lead to inaccurate odometry.

- Minimize Slippage: Reduce wheel slip by optimizing motor power and wheel friction.

- Test Regularly: Run tests in different environments to fine-tune the system.

- Implement PID Control: A PID controller helps achieve smoother and more responsive movements.

Common Challenges and Solutions

- Inconsistent Readings:

- Cause: Sensor errors or wheel slippage.

- Solution: Regular calibration and high-quality components.

- Complex Programming:

- Cause: Mecanum drive requires intricate motor coordination.

- Solution: Use existing templates or libraries to simplify development.

- Battery Drain:

- Cause: High motor power consumption.

- Solution: Optimize motor efficiency and limit unnecessary movements.

Real-World Applications of Mecanum Drive with Odometry

- Robotics Competitions: Efficiently navigate complex fields and complete autonomous tasks.

- Warehouse Robotics: Maneuver in tight spaces to transport goods.

- Exploration Robots: Navigate unknown terrains with precision.

FAQs About Mecanum Drive Template Odometry

Q1: What programming language is used for VEX V5 Mecanum drive odometry?

A: VEX V5 uses C++ in VEXcode Pro V5. Python is also an option for simpler implementations.

Q2: Can I use Mecanum drive without odometry?

A: Yes, but odometry significantly enhances precision, especially for autonomous tasks.

Q3: Are there prebuilt odometry libraries for mecanum drive template odometry vex v5?

A: Yes, many robotics communities share odometry templates and libraries online. These can save time and effort.

Q4: How do I handle wheel slippage in odometry calculations?

A: Implementing slip correction algorithms or using additional sensors like gyroscopes can help mitigate slippage errors.

Q5: Is mecanum drive template odometry vex v5 robotics competitions?

A: While it offers excellent maneuverability, mecanum drive template odometry vex v5 drive may not be ideal for terrains requiring high traction.

Conclusion

mecanum drive template odometry vex v5 represents a cutting-edge approach to robotics navigation. Its combination of omnidirectional movement and precise positional tracking offers unmatched flexibility and control. By understanding the principles and following best practices, you can harness this technology to build advanced robotics systems that excel in competitions and real-world applications.

Whether you are a beginner or an experienced builder, the integration of mecanum drive template odometry vex v5 drive and odometry opens the door to innovative possibilities in robotics engineering.