Introduction to Asbestlint

Asbestlint is a material that has been widely used in various industries due to its heat-resistant and insulating properties. Made from asbestos fibers, asbestlint has been incorporated into construction, automotive, and manufacturing applications. However, despite its functional benefits, asbestlint poses significant health risks, leading to strict regulations and bans in many countries.

This article explores the nature of asbestlint, its historical uses, associated health hazards, and modern alternatives. By understanding these aspects, individuals and industries can make informed decisions regarding safety and compliance.

What Is Asbestlint?

Asbestlint is a type of woven or braided material composed of asbestos fibers. Asbestos, a naturally occurring mineral, is known for its durability, fire resistance, and insulating capabilities. These properties made asbestlint a popular choice for:

-

Thermal insulation (pipes, boilers, furnaces)

-

Electrical insulation (wiring, electrical panels)

-

Fireproofing (protective clothing, fire blankets)

-

Gaskets and seals (automotive and industrial machinery)

Due to its fibrous nature, asbestlint was easy to mold into different shapes, making it versatile for industrial applications.

Historical Uses of Asbestlint

Before the dangers of asbestos were fully understood, asbestlint was extensively used in various sectors:

1. Construction Industry

Asbestlint was commonly used in buildings for insulation, pipe wrapping, and fireproofing. Its ability to withstand high temperatures made it ideal for protecting structural components.

2. Automotive Industry

In vehicles, asbestlint was used in brake linings, clutch pads, and gaskets to prevent overheating and friction-related wear.

3. Manufacturing and Industrial Applications

Factories utilized asbestlint in machinery insulation, protective gear, and high-temperature sealing due to its resilience.

Despite its widespread use, the health risks associated with asbestos exposure led to a decline in its usage over time.

Health Risks Associated with Asbestlint

The primary concern with asbestlint is its potential to release microscopic asbestos fibers into the air. When inhaled, these fibers can cause severe respiratory diseases, including:

1. Asbestosis

A chronic lung condition caused by prolonged asbestos exposure, leading to scarring of lung tissue and breathing difficulties.

2. Mesothelioma

A rare and aggressive cancer affecting the lining of the lungs, abdomen, or heart, directly linked to asbestos exposure.

3. Lung Cancer

Asbestos fibers can contribute to the development of lung cancer, especially in smokers.

4. Pleural Thickening

A condition where the lining of the lungs thickens, causing chest pain and restricted breathing.

Due to these risks, many countries have imposed strict regulations or outright bans on asbestos-containing materials, including asbest lint.

Regulations and Bans on Asbest lint

Governments worldwide have recognized the dangers of asbestos and implemented laws to limit its use:

-

European Union: Banned all forms of asbestos.

-

United States: Heavily regulated, with partial bans on certain asbestos products.

-

Australia: Completely banned asbestos use and import.

These regulations require proper handling, removal, and disposal of asbestos-containing materials to minimize exposure risks.

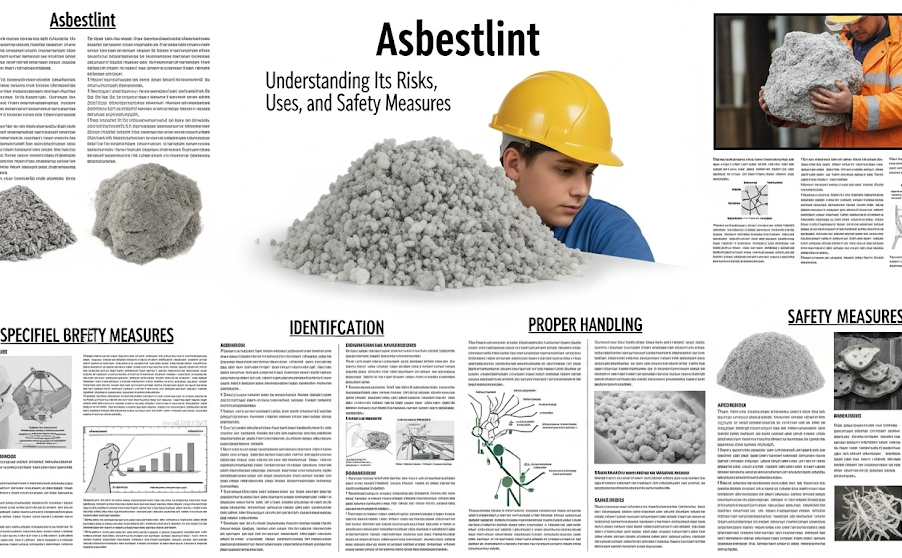

Safe Handling and Removal of Asbest lint

If asbest lint is present in older buildings or equipment, proper safety measures must be followed:

1. Professional Inspection

Only certified asbestos inspectors should assess the presence and condition of asbest lint.

2. Proper Removal Procedures

Licensed asbestos abatement professionals must handle removal to prevent fiber release.

3. Personal Protective Equipment (PPE)

Workers should wear respirators, gloves, and disposable coveralls to avoid exposure.

4. Disposal in Designated Facilities

Asbestos waste must be sealed and disposed of in approved hazardous waste sites.

Ignoring safety protocols can lead to severe health consequences for workers and building occupants.

Modern Alternatives to Asbest lint

Due to health concerns, safer alternatives have replaced asbest lint in most applications:

1. Fiberglass

A common substitute for insulation, offering similar heat resistance without the health risks.

2. Ceramic Fibers

Used in high-temperature environments, such as industrial furnaces and kilns.

3. Aramid Fibers (Kevlar)

Provides durability and heat resistance in protective clothing and automotive parts.

4. Cellulose-Based Insulation

An eco-friendly option made from recycled paper, treated for fire resistance.

These alternatives provide comparable performance without the hazardous effects of asbestos.

Conclusion: The Future of Asbest lint and Safety Awareness

While asbest lint was once a staple in industrial and construction applications, its health risks have led to its decline. Strict regulations, safer alternatives, and increased awareness have minimized its use. However, legacy asbestos products still pose risks in older structures, requiring careful management.

By prioritizing safety, proper handling, and modern substitutes, industries can protect workers and the public from asbestos-related diseases. Continued education and compliance with regulations are essential to eliminating the dangers of asbest lint completely.

Final Thoughts

Understanding the risks and proper handling of asbest lint is crucial for anyone working in construction, renovation, or industrial maintenance. Staying informed ensures a safer environment for all.